Weld Mesh Fencing & Fence Post,Gates - For Oil Fields Security, Fencing Mesh Protected by Zinc Coating And Polyester Coating, Fence Top with Barbed Wire Installation

We supply hot dipped galvanized welded wire fence and powder coated galv. welded wire fence. Trellis netting has a hole of various sizes. Anti cut and anti climbing small aperture mesh is popularly used in high security fencing projects for oil fields, gas plants and other sites demanding high level protection.

Fence Panels, Posts, Fixing accessories, Gates, Short Barb Wire, Medium Barb Razor Wire of all kinds and specifications are supplied for construction a security fencing project.

Barbed Wire PVC Coated Galvanised and Razor Tape Concertina Coils including the poles and all the necessary items related for concertina installation.

Processing and Surface Treatments:

The panels are welded by high quality cold drawn steel wire, after hot dipped galvanized, or to weld the panel with cold drawn wire, then to be galvanized. Galvanized wire panels have additional protection with powder sprayed coating or PVC / PE dipped coating. Mesh fences treated with the zinc coating, powder or PVC / PE coating have a life span of min. 10 years.

General Weld Mesh Panels with Posts:

| Wire Dia. | Mesh Size | Panel Width | Panel Height | Fold No. | Posts height | Post Model | ||

| Fix I | Fix II | Fix III | ||||||

| 4.0 mm 4.5 mm 5.0 mm 5.5 mm 6.0 mm |

200 x 50 mm 200 x 55 mm 200 x 60 mm 200 x 6 5mm |

2.0m 2.255m 2.5m 3.0m |

0.635 m | 2 | 0.9 | 0.7 | 1.0 | Peach shape post V type post |

| 0.835 m | 2 | 1.2 | 0.9 | 1.2 | ||||

| 1.035 m | 2 | 1.4 | 1.1 | 1.4 | ||||

| 1.235 m | 2 | 1.6 | 1.3 | 1.6 | ||||

| 1.435 m | 2 | 1.8 | 1.5 | |||||

| 1.535 m | 3 | 1.9 | 1.6 | |||||

| 1.635 m | 3 | 2.0 | 1.7 | |||||

| 1.735 m | 3 | 2.2 | 1.8 | |||||

| 1.835 m | 3 | 2.3 | 1.9 | |||||

| 1.935 m | 3 | 2.4 | 2.0 | |||||

| 2.035 m | 4 | 2.5 | 2.1 | |||||

| 2.235 m | 4 | 2.8 | 2.3 | |||||

| 2.435 m | 4 | 3.0 | 2. | |||||

Fence panels can be flat / straight, or curved:

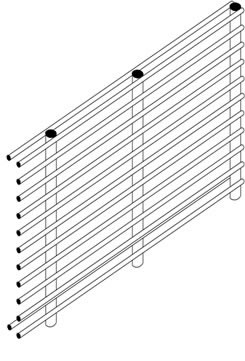

Weld Mesh Curved Fencing Panels

Curved wire mesh panel:

2400mm x 1800mm

Finish: Galvanized

Mesh hole : 50*200 mm

Wire diameter : 5 mm

Delivered to Sydney Australia for perimeter security

HIGH SECURITY FENCE – WELDED MESH & GATES - FOR OIL FIELDS

High Security Welded Mesh with fencing materials, Sliding Security Gates, Swing Gate with Double Leaf Security Gates and ALL accessorie.

High Security Fence - Welded Mesh

High Security Welded Mesh is supplied and delivered in accordance to following quality:

EN 10016-2: Non-alloy steel rod for drawing and / or cold rolling.

EN 10218-2: Steel wire and wire products – Part 2: Wire dimensions and tolerances.

EN 10223-7: Steel wire and wire products for fences – Part 7: Steel wire welded panels for fencing.

EN 10244-2: Steel wire and wire products – No ferrous metallic coating on steel wire- Part 2: Zinc or zinc alloy coating on steel wire.

EN 10245-1: Steel wire and wire products – Organic coating on steel wire Part 1: General rules

FENCING CONSTRUCTIONS

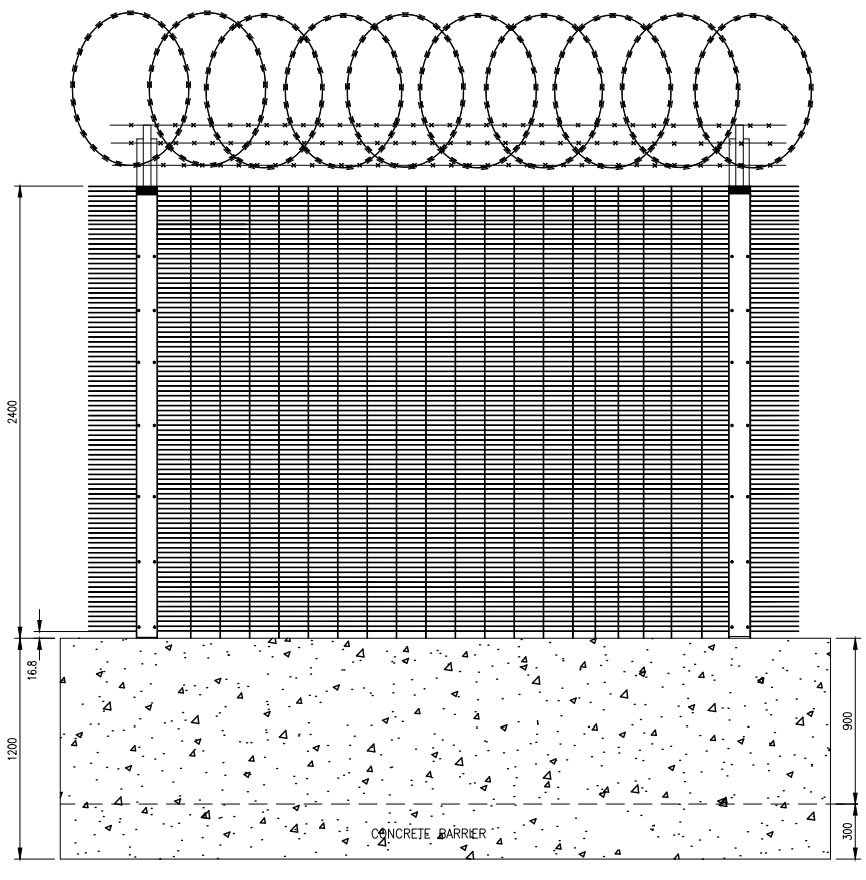

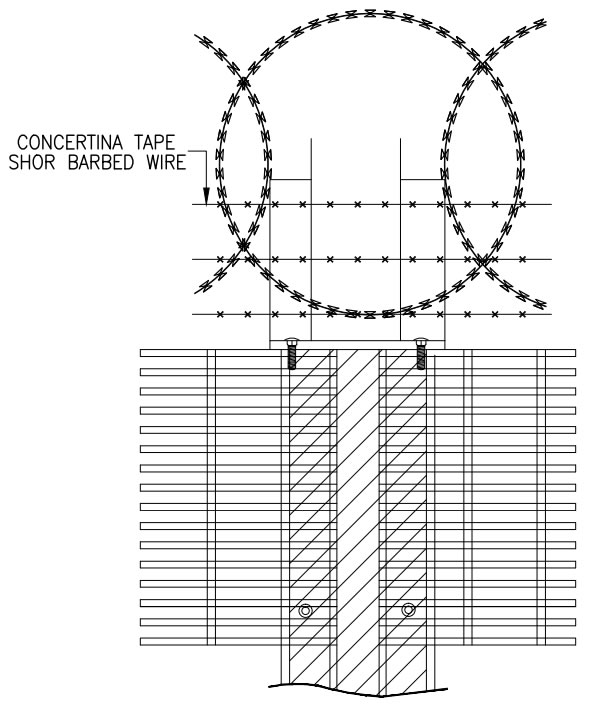

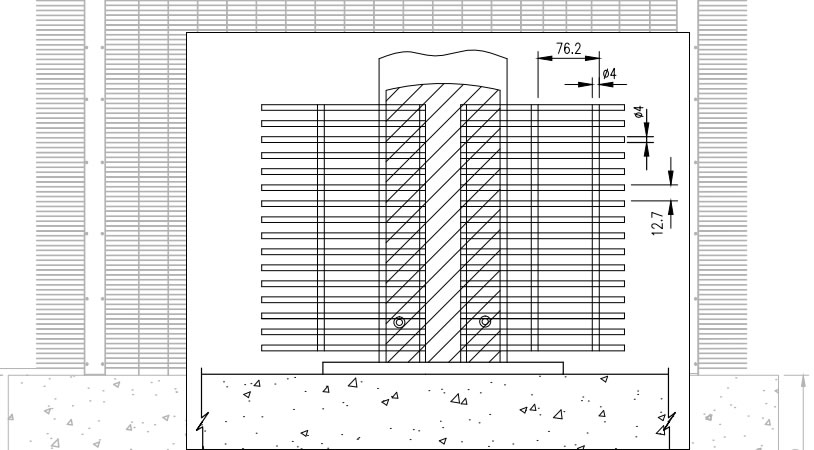

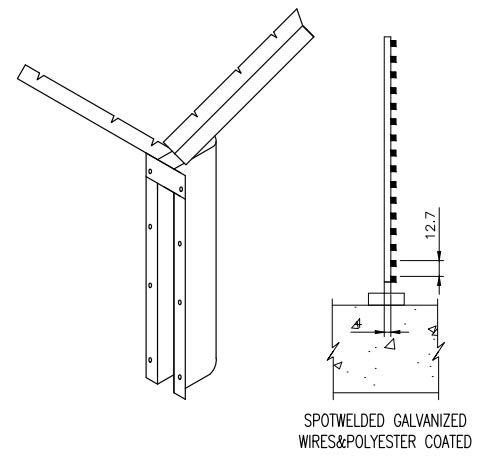

Fence panel: High security welded mesh fencing panels are made of galvanized steel wires, welded and subsequently polyester-coated, using fence panels of height 2.42 M supported by continuous concrete ground beam. The panels have round horizontal wires and thicker round vertical wires. The horizontal wires are double every 1210 mm, starting with a double wire at the bottom and ending with a double wire at the top.

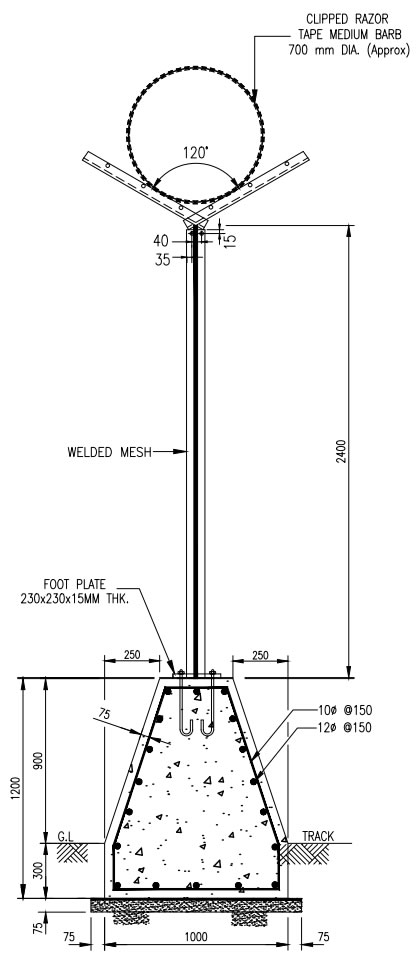

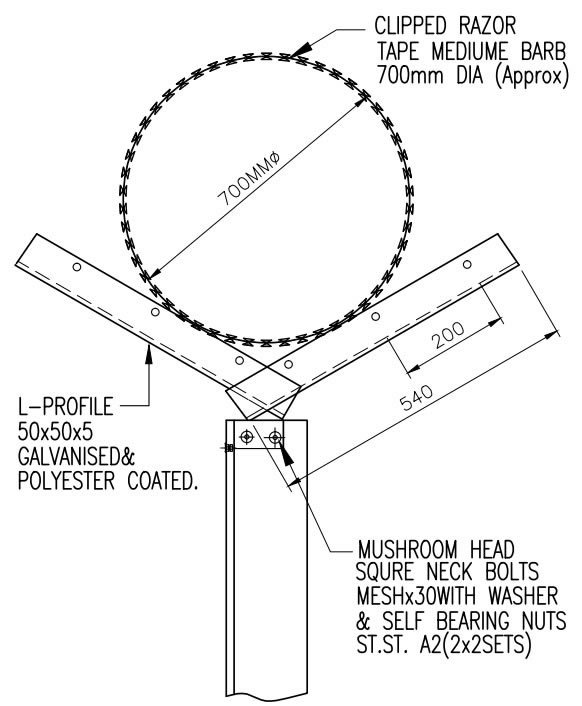

Fence top of barbed wire and razor wire:

External face of fence is to be fitted with single coil of clipped razor tape medium barb on top. Corner and Line posts are fitted with extension arms which shall support six horizontal strands of concertina tape short barbed wire, 3 on each side. The extension arms and barbed wire is to support a single coil of clipped razor tape of 700 mm diameter on top of the fence.

Flat mesh panel:

FENCING MATERIAL

Fence Panels

The panels are produced by electrical resistance welded galvanized wires and subsequently polyester-coated.

Panel sizes:

Height of the Panel

190x12.7 = 2413, 0 + 2.5 mm measured centre-centre. The overall height is 2416 + 3 mm.

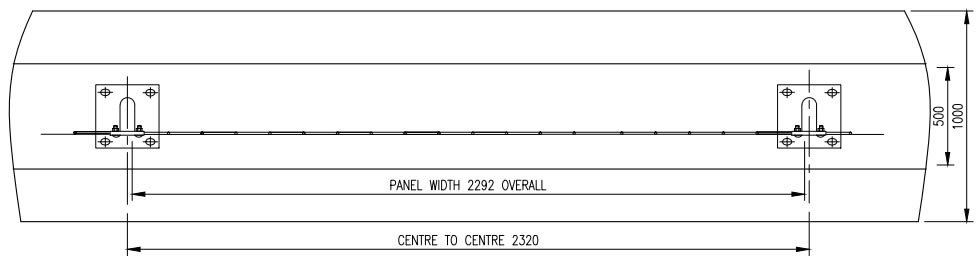

Width of the Panel

The standard width is 30 x 76.2 = 2286+ 2.5 mm, measured from centre to centre. The overall width, excluding overhangs, is 2292 + 3 mm.

Mesh Dimensions and Tolerances

The nominal mesh dimensions are measured between the centers of two neighboring wires:

Distance between the vertical wires: 76, 2 + 2 mm

Distance between the horizontal wires: 12, 7 + 1 mm

Wire Diameter

Diameter of the horizontal wires: 4.00 + 0.08 mm

Diameter of the vertical wires: 6.00 + 0.09 mm

Tensile Strength

Horizontal wires: 600 to 810 N/mm2.

Vertical wires: 400 to 550 N/mm2.

Wire Rod:

European standard EN 10016-2.

Chemical composition:

| Chemical composition | |

| Element | % |

| C < 0.10 Si < 0.30 Mn < 0.60 P < 0.035 S < 0.035 |

|

Surface Treatment:

Mesh fences are protected by zinc coating and polyester coating.

Metallic Coating

The wires are galvanized and the minimum zinc weight:

- For the horizontal wires is 275 g/m2.

-

For the vertical wires is 290 g/m2.

Organic coating

The panels after welding and zinc coating is subsequently polyester coated. The layer thickness is determined by taking the average of 10 measurements on 1 panel and shall be minimum 150μm.

Polyester coating meets following quality:

Adhesion test of the polyester powder coating : make scratch in the longitudinal directional of the wire, by means of a hard metal pointed graving tool penetrating through the metal. The length of the scratch will be about 50mm. The coating shall not be able to be lifted from the metal by more than 5 mm.

Resistance of the polyester to salt spray: make a scratch in the longitudinal directional of the wire by means of a hard metal pointed graving tool penetrating through the metal. The length of the scribe will be about 50mm. Test in accordance with ISO 9227. After 1000 h there shall be no under film corrosion or loss of adhesion in excess of 10 mm from the scratch and no signs of blistering, cracking or crazing on any part of the specimen.

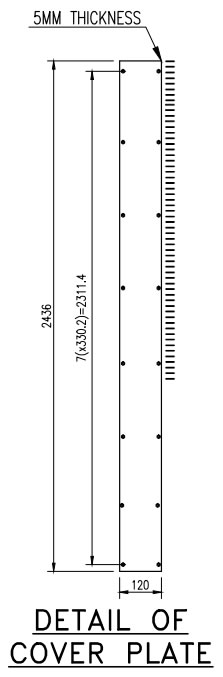

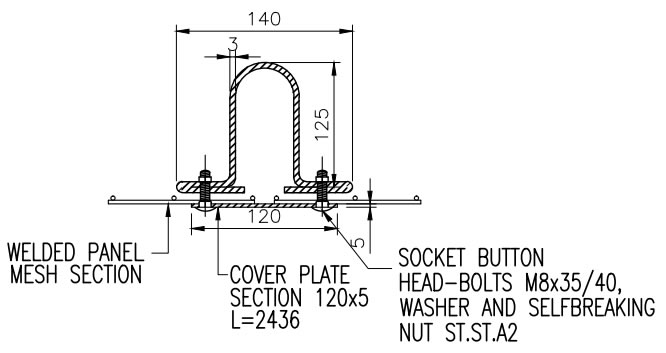

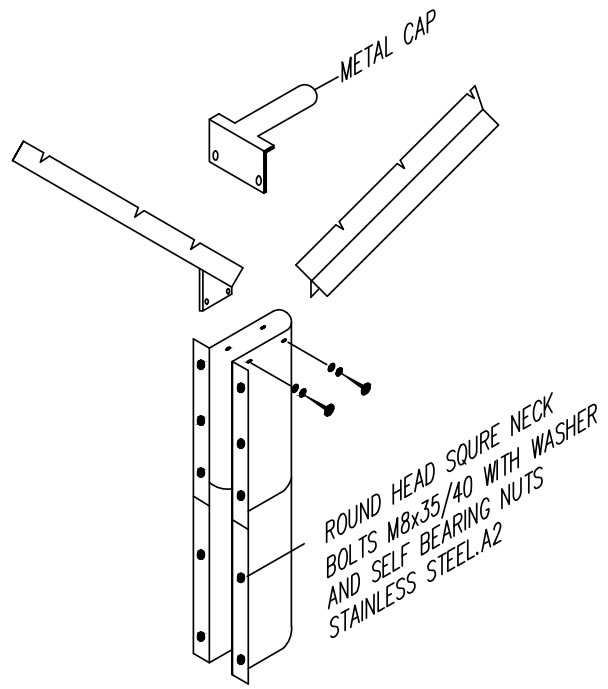

Panels Installation

Welded mesh panels are fabricated to correspond with the width and height specified. Welded mesh panels are attached with a continuous cover plate120 x 5 x 2436 mm with pre-drilled slots, galvanized and polyester- coated at a spacing of 330.2mm, connected to the vertical post with socket button head-bolts M8 x 35/40, washer and self bearing nuts St.St.A2.

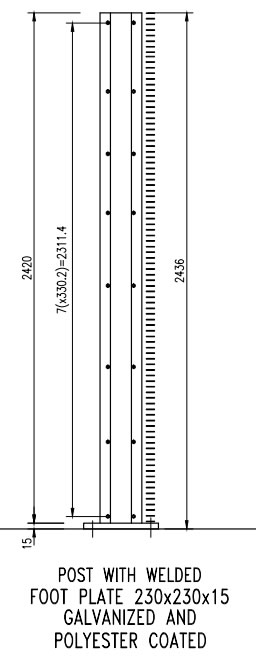

FENCE POST

Fence posts are made of steel and are hot-dip galvanized and polyester coated afterward. The posts are holed to facilitate assembly of the components.

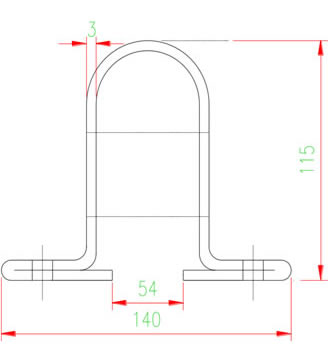

Fence post shall be with section: 140 x 115 x 3

A steel foot plate shall be welded to the bottom of the fence post.

Post Materials

The materials and constructions of the posts shall conform to the applicable sections of the following documents:

EN 10027-1: Designation system for steel – Part 1: Steel names.

EN 10292: Continuous hot-dip coated strip and sheet of steels with higher yield strength for cold forming – Technical delivery conditions

EN 13438: Powder organic coatings for galvanized steel products for construction purposes

ISO 1461: Hot dip galvanized coatings on fabricated iron steel Articles- specifications and test methods.

Designation of the steel for the fence post: H380LAD Z 275 MAC, in Accordance with EN 10292

Posts are made from steel having Minimum yield strength: 380 N/mm2.

Chemical composition:

| Table 1: chemical composition | |

| C | < 0.10% |

| Si | < 0.50% |

| Mn | < 1.40% |

| P | < 0.025% |

| S | < 0.025% |

| Al | < 0.015% |

Posts Finishes: Zinc Coating and Polyester Coating

Metallic coating

The Posts are made from continuously hot dip galvanized steel strip. Minimum zinc coating weight: 395 g/m2, in accordance with ISO 1461

Organic coating

The posts are after welding subsequently polyester coated. The layer thickness is determined by taking the average of 10 measurements on 1 panel and shall be minimum 100μm

Adhesion of the polyester: make a X-cross in the coating, by means of a hard metal pointed graving tool penetrating through the metal. The length of the scratches will be about 50 mm. The coating shall not be able to be lifted from the metal by more than 5 mm.

Resistance of the polyester to salt spray: make a X-cross in the coating by means of a hard metal pointed graving tool penetrating through the metal. The length of the scribe will be about 50 mm. Test in accordance with ISO 9227. After 1000 h there shall be no under film corrosion or loss of adhesion in excess of 10 mm from the scratch and no signs of blistering, cracking or crazing on any part of the specimen.

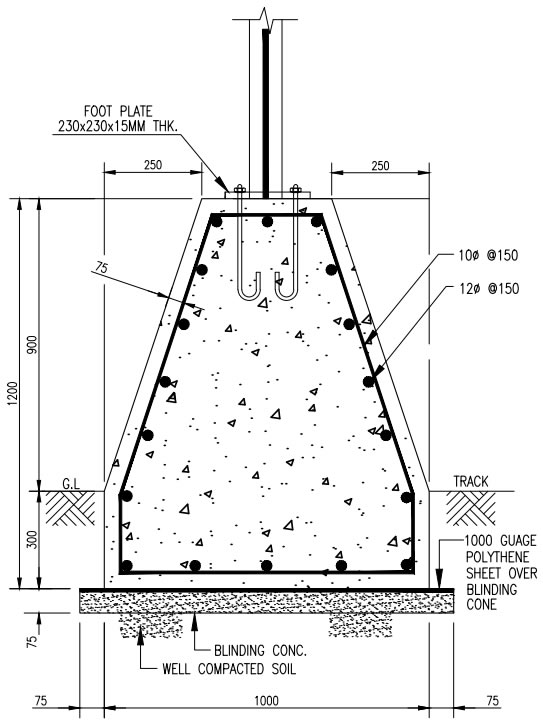

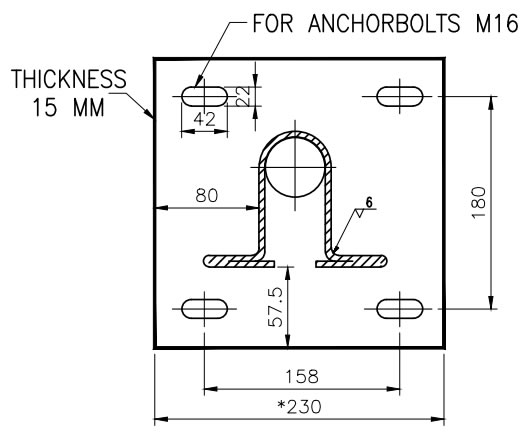

Post Foundations and Fixing

Fence posts shall be constructed with a welded foot plate of minimum size 230 mm x 230mm x 15mm, galvanized and polyester –coated, which shall be secured by 4 x chemical Anchor bolts of minimum diameter 16mm and overall concrete penetration 300mm.

Concrete: All reinforced concrete shall be of (K-300) having a minimum characteristic cube crushing strength of 30 N/mm2 at 28 days and for the blinding / plain concrete shall be of (K-150) having a characteristic crushing strength of 15.7 N/mm2 .

Reinforced Steel: Steel reinforcement for reinforced concrete shall be deformed bars meeting the requirements of ASTM A 615 / A 615M.

Continuous sections may be constructed as pre-cast or in-situ units. Adequate movement joints shall be provided. The foundation wall is not intended to retain any internal spillage. Drainage passages shall be incorporated in the section such that any spillage will not be retained and free passage of liquids through the boundary fence is permitted. Passages must be such sizes to prevent intruder entrance and also prevent their blockage by wind blown debris and sand.

Trenches for the foundation shall be carefully leveled and compacted. A layer of blinding concrete of minimum thickness 75mm shall be laid over 1000 gauge polythene sheet.

Anchor Bolts

4 Nos. of chemical Anchor Bolts M16 size with locking nut shall be hot dip galvanized finish.

Floor Plate

230 x 230 x 15mm thick foot plate welded with fence post shall be electronically galvanized and polyester- coated

Minimum yield strength: 235 N/m2.

Site Preparation

Prior to the installation, all necessary grading & cleaning on both sides of fences shall be performed.

Grading shall be done in such a manner as to provide a straight flat and level surface.

Soil or stone fill shall be thoroughly compacted.

FENCE TOP AND INSTALLATION

V Extension Arm for Barbed Wire

The extension arms shall be fitted on the top of the posts. The installed arm must be capable of supporting a minimum of 125 kg dead weight attached to the outer end of the arm. The arm shall be rigidly fixed on the post by means of mushroom head square neck bolts M8 x30 with washer and self bearing nuts St. St A2 (2 x two sets)

Concertina Tape Short Barbed Wire

Galvanized and polyester- coated concertina barbed wire supplied to be mounted above welded mesh panels

Clipped Razor Tape

Stainless steel clipped razor tape medium barb, polyester - coated, to be mounted above welded mesh panel and concertina barbed wire strands.

CCTV monitor system and motion detector can be installed with the high security fence system.

SECURITY GATES

Two types:

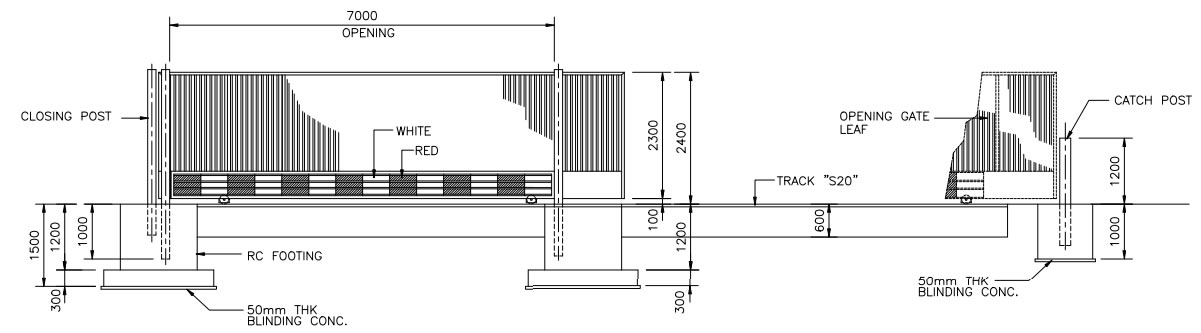

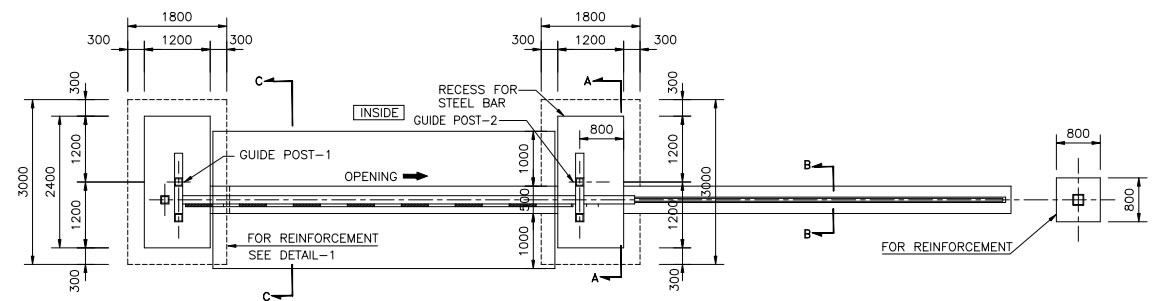

Sliding Security Gates, 7m (w) x 2.4m (h)

Swing Gate with Double Leaf Security Gates, 20m (w) x 2.4m (h)

Heavy Duty, Crash Rated and Certified Gate. Materials and construction conform to following standards:

a) American Society for Testing Materials Standards – Parts 1 & 2.

b) AASHTO M181.

c) State General Safety Orders.

Gate General Construction:

The gate is one piece and horizontally sliding being constrained by track and rollers. The gate shall be above grade assembly consisting of a heavy steel structure capable of being opened and closed in a linear motion. When in a closed position it shall present a formidable obstacle to approaching vehicles and prevent intruder ingress. Upon impact, forces shall first be absorbed by the gate assembly and then transmitted to the supporting buttresses and their foundations.

The gate is to be of minimum height from the finished concrete floor surface of 2.4 meters and the maximum vertical distance between its bottom rail and the adjacent ground level is to be 100mm.

The lower portion of the gate shall constitute a crash beam designed to withstand a vehicle impact. The gate shall be designed so that in the closed position it will prevent the penetration of a 15 tonne vehicle hitting it at 40km per hour.

Vertical extension arms shall be fitted to gate vertical members and configured in such a way to avoid tangling with fence or wall barbed wire when the gate is opened. The layout of the entrance is to be such that “windows” in the razor tape topping the fence and gate do not occur through which intruders may affect entry.

TECHNICAL DESCRIPTION:

7.0meters wide & 2.4 meters high sliding gates:

Sliding gate on ground track, electrically and manually operated, single leaf construction, heavy duty crash rated type for impact resistance <500 kN (K4/K8)

Clear passage width: 7000 mm

Gate height from FFL: 2400 mm (incl. 100 mm ground clearances)

Direction of Opening: able to be specified as left or right opening

Swing gate on ground track for Rig movement, electrically and manually operated, double leaf construction, heavy duty crash rated type for impact resistance <500 kN (K4/K8)

Clear passage width: 20000 mm

Swing gate height from FFL: 2400 mm (incl. 100 mm ground clearances)

Gate Frame:

Bottom rail made of RHS 700/300 and additionally with special IAD- device (Impact Absorption Device “red/white” striped) at the outside for easy exchangebility in case of minor impacts by accident.

Side stiles and top rail made of RHS 180/160.

Vertical reinforcement bars made of RHS 100/100.

The inside of bottom rail must be equipped with special tooth rack and provision for later gate motorization.

Frame Infill:

Made of rectangular bars RHS 40/30 welded in between top and bottom rail max. 120 mm clear distance.

Gate Posts:

Double guide posts and double stop post with special inner impact reinforcement beams HTS/P 220.

Posts made of square steel section 280/280 for reinforced concreting-in min 1600 mm in depth.

Supporting Structures:

Special steel rollers D200 on ball bearings (lifetime lubricated) are installed within the bottom rail of the gate leaf.

A special steel ground track S 20 with concrete anchors carries the gate rollers.

Gate lock:

1 no. special security lock for electrically and manually operated gates at front leading edge of sliding gate, locked at stop post.

Corrosion protection:

Very special galvanized and plastic coated for maritime and extreme weather conditions according to the 4-S-Coating (as per attached detailed technical description).

Colour of plastic coating according to standard RAL-chart.

Long-Term Corrosion Protection - 4S-Coating

The long-term corrosion protection will consist of a four-step process with three surface layers providing the perfect protection for every climate. The thickness of the complete corrosion protection layers is approx. 260µ.

STEP 1: Preparation (Clean-Blasting of the steel surface)

The basic preparation of steel surfaces for an optimal application of the corrosion protection layers is the perfect cleaning. All metal parts are blasted clean according to Swedish standard SIS 055900, level Sa3 to obtain a surface with a special defined surface roughness. This surface structure is the optimal basis for the subsequent application of the corrosion protection layers.

STEP 2: First Layer (Galvanizing of the surface by arc galvanizing)

Immediately after the clean blasting process 100% pure zinc is applied to the blasted clean steel surface by electrical arc galvanizing according to DIN 8565 and DIN 8566. During this process zinc wire is melted in the arc with very high temperatures and is applied to the steel surface from a short distance. The extremely hot and liquid zinc turns into a fused adhesive coating with the rough steel surface. The minimum thickness of the layer is 100µ. An important advantage of arc galvanizing is the small quantity of heat being transferred to the steel surface. This prevents thermal distortion of the material.

STEP 3: Second Layer(First plastic coating)

Either 2-component coating or powder coating. Minimum thickness of the layer is 80µ .

STEP 4: Third Layer (Second plastic coating)

Either 2-component coating or powder coating. Minimum thickness of the layer is 80µ .

Finished Corrosion Protection

The minimum thickness of the finished coating is approx. 260 µ.

All gates must be factory tested and comply with the acknowledged rules of technology especially with the rules 89/392/EWG (CE), BGR 232, and DIN EN 13241.

Gate Installation

Our mesh fences are not limited to oil fields, we can design, process and supply high security fencing products to suit a variety of protection needs.