Supply & Installation Of Wire Mesh Security Fence System

Security fencing system usually combines wire mesh fencing fabrics or panels and the fencing toppings like barbed wire, concertina wire or spikes topping together.

Mesh Fencing Fabrics:

Chain link, welded mesh, 358 mesh, woven wire mesh, expanded metal and more.

Features: Security mesh fence has high strong powers to resist the concussion. Serried horizontal wires have good ability to anti-climb. While the line of sight is well to see the inner things .This kind of wire fence is the best choose of the High Security Area.

Temporary Security fencing offers a cost effective temporary solution to protect your premises. We have access to a large supply which enables us to provide great rates and service.

Security Fencing Dimensions: Length 3.5metres; Height 2metres.

Toppings for security fencing are usually wall spikes, barbed wire, razor wire or concertina wire coils.

SECURITY FENCE MANUFACTURED AND SUPPLIED FOLLOWING ASTM INTERNATIONAL (ASTM) STANDARD

| ASTM A116 | (2011) Standard Specification for Metallic-Coated, Steel Woven Wire Fence Fabric |

| ASTM A121 | (2013) Standard Specification for Metallic-Coated Carbon Steel Barbed Wire |

| ASTM A153/A153M | (2016) Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware |

| ASTM A240/A240M | (2016) Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications |

| ASTM A478 | (1997; R 2013) Standard Specification for Chromium-Nickel Stainless Steel Weaving and Knitting Wire |

| ASTM A702 | (2013) Standard Specification for Steel Fence Posts and Assemblies, Hot Wrought |

| ASTM A780/A780M | (2009; R 2015) Standard Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings |

| ASTM A824 | (2001; R 2012) Standard Specification for Metallic-Coated Steel Marcelled Tension Wire for Use With Chain Link Fence |

| ASTM C94/C94M | (2016) Standard Specification for Ready-Mixed Concrete |

| ASTM F1043 | (2016) Strength and Protective Coatings on Metal Industrial Chain-Link Fence Framework |

| ASTM F1083 | (2016) Standard Specification for Pipe, Steel, Hot-Dipped Zinc Coated (Galvanized) Welded, for Fence Structures |

| ASTM F1184 | (2016) Industrial and Commercial Horizontal Slide Gates |

| ASTM F567 | (2014a) Standard Practice for Installation of Chain Link Fence |

| ASTM F626 | (2014) Standard Specification for Fence Fittings |

| ASTM F668 | (2011) Poly(Vinyl Chloride) (PVC) and other Organic Polymer-Coated Steel Chain-Link Fence Fabric |

| ASTM F883 | (2013) Padlocks ASTM F900 (2011) Industrial and Commercial Swing Gates |

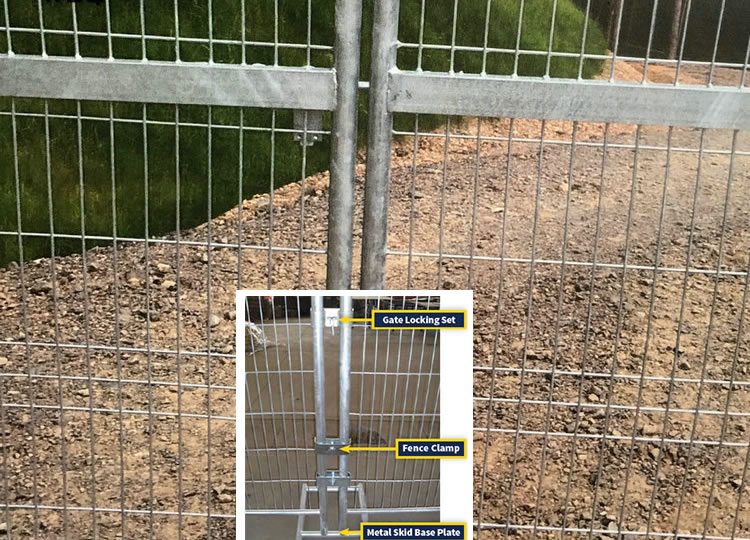

No-climb wire mesh modular security fence system

We supply no-climb wire mesh modular security fence system ideal for perimeter security. Modular fence must be strong, reliable, galvanized, steel, and can stand through hurricane winds. Modular fence panel is durable, 16-gauge, hot-dipped galvanized tubing with a welded, no-climb wire mesh panel. Sections interlock using easy-to-install clamps with metal or concrete bases. Supplied with four entry point gates for the modular fence entry point.

• Each modular fence section/panel is: Length is 10 ft., height is 9 ft., and weight is at least 90 lbs.

Entry Point Gates are: 3 FT wide, 9FT high and at least 90 LBS. Supplied with total 4 entry point gates.

Security Modular Fence

Entry Point Gates:

LENGTH: At least 3 FT Wide

HEIGHT: At least 9 FT

WEIGHT: At least 90 LBS

Modular anti climbing security fence system with durable welded wire mesh panel framed with hot-dipped galvanized tubing

Sections interlock using easy-to-install metal clamps and metal or concrete bases for support.

galvanized steel, that will not rust due to changing weather.

Perimeter Security Fencing System - High-Security Chain-Link Mesh Fences And Gates

Construct Fence Alignment include PVC-coated chain-link fabric.

FENCE FABRIC

Provide Class 2b polyvinyl chloride-coated steel fabric with 92 grams of zinc coating per square meter in accordance with ASTM F668. Fabricate fence fabric of 9 gauge wire woven in 50 mm mesh conforming to ASTM A116. Polyvinyl chloride coating for fabric and all other fence components shall be manufacturer's standard color, as selected by Contracting Officer. Fabric shall be twisted and barbed on the top selvage and knuckled on the bottom selvage. Secure fabric to posts using stretcher bars or ties spaced 375 mm on center, or by integrally weaving to integral fastening loops of end, corner, pull, and gate posts for full length of each post. Install fabric on opposite side of posts from area being secured.

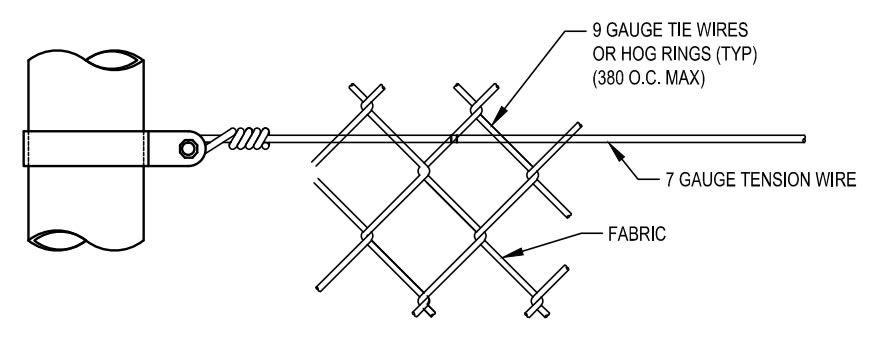

Tension Wire Attachment

Metal Posts for Chain Link Fence

Provide posts conforming to ASTM F1083, zinc-coated. with external coating steel pipe. steel pipe, zinc-coated with external coating , roll-formed steel sections, meeting the strength and coating requirements of ASTM F1043 and ASTM A702. Post shall be either steel pipe, roll-formed steel sections, and be zinc coated conforming to the requirements of ASTM F1043. Line posts and terminal (corner, gate, and pull) posts selected shall be of the same designation throughout the fence. Provide gate post for the gate type specified subject to the limitation specified in ASTM F900.

Accessories

a. Provide accessories conforming to ASTM F626. Ferrous accessories shall be zinc coated.

b. Furnish truss rods for each terminal post. Provide minimum nominal diameter 8 mm truss rods with turnbuckles or other equivalent provisions for adjustment.

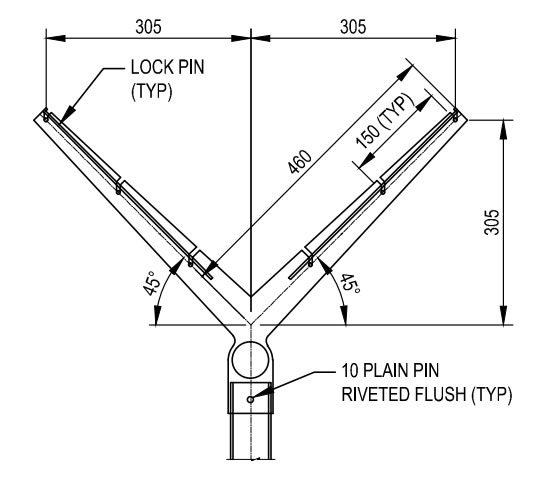

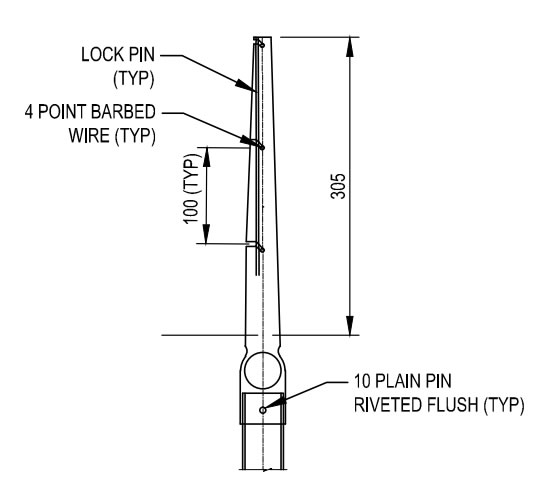

c. Provide Barbed wire supporting arms of the V 6 strand arm type and of the design required for the post furnished. Secure arms by riveting to post, spacing at no more than 3050mm intervals.

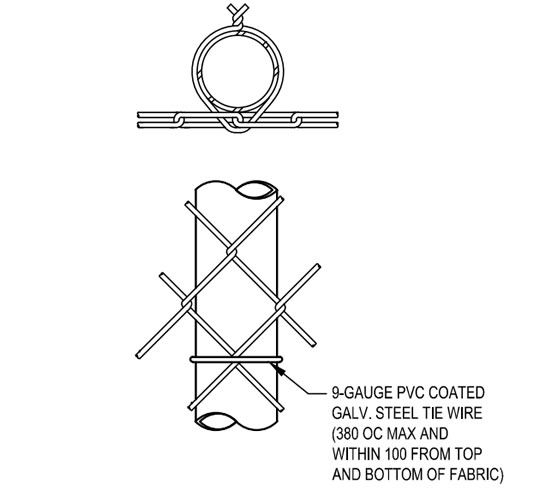

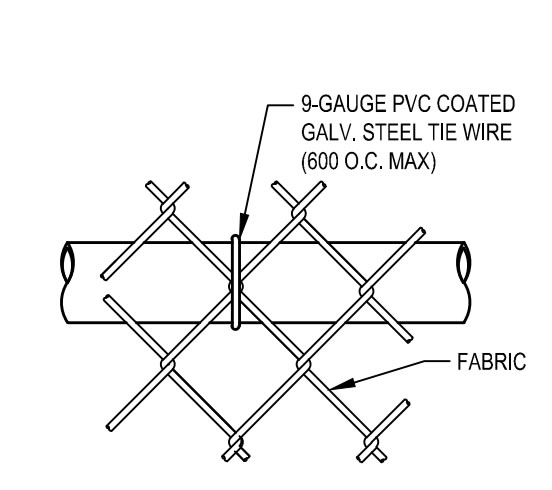

d. Provide 9 gauge steel tie wire for attaching fabric to rails, braces, and posts and match the coating of the fence fabric. Miscellaneous hardware coatings shall conform to ASTM A153/A153M unless modified.

Post And Rail Attachment

BRACES AND BOTTOM RAIL

ASTM F1083, zinc-coated, steel pipe, size NPS 1-1/4. Group IC steel pipe, zinc-coated, shall meet the strength and coating requirements of ASTM F1043. Braces and bottom rail shall be steel pipe, size NPS 1-1/4, formed steel sections, size 42 mm outside diameter by 3.56 mm minimum wall thickness and be zinc coated conforming to the requirements of ASTM F1043.

Wire Ties

Submit samples as specified. Provide wire ties constructed of the same material as the fencing fabric with polyvinyl (PVC) coating.

Barbed Wire

Provide barbed wire conforming to ASTM A121 zinc-coated, Class 3, or aluminum-coated, with 12.5 gauge wire with 14 gauge, round, 4-point barbs spaced no more than 102 mm apart.

Tension Wire

Provide Class 4 coating, in accordance with ASTM A824. Provide 7 gauge coil spring wire for top wire.

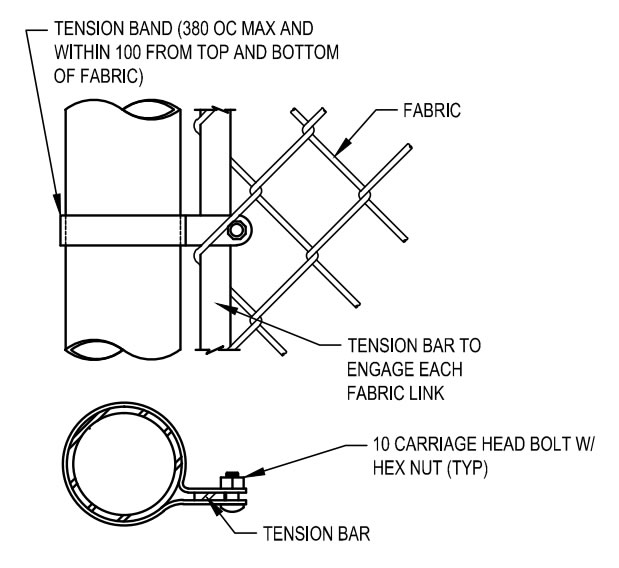

Tension Bar

BARBED TAPE COIL

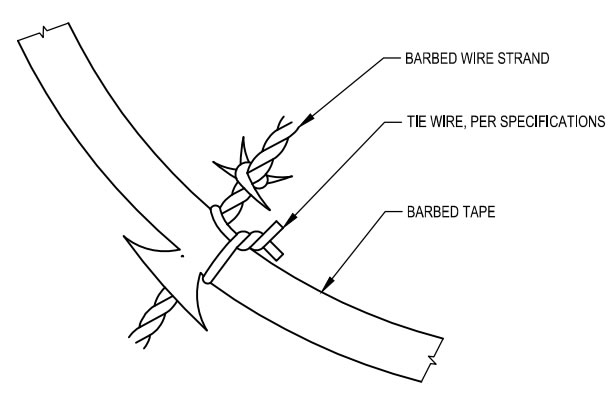

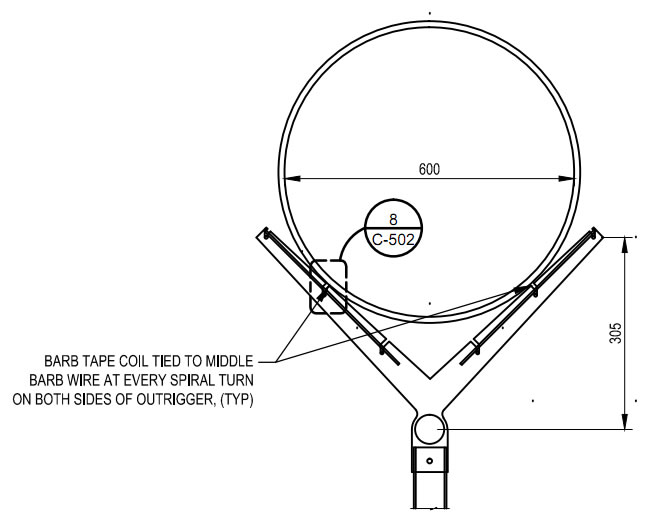

Provide reinforced barbed tape, single coil, for fence toppings fabricated from 430 series stainless steel with a hardness range of Rockwell (30N) 37-45 conforming to the requirements of ASTM A240/A240M. Provide stainless steel strip 0.6 mm thick by 25 mm wide before fabrication. Each barb shall be a minimum of 30.5 mm in length, in groups of 4, spaced on 102 mm centers. The stainless steel core wire shall have a 2.5 mm diameter with a minimum tensile strength of 9.68 MPa and be in accordance with ASTM A478. Use sixteen gauge stainless steel twistable wire ties for attaching the barbed tape to the barbed wire.

Barbed Tape Option

ASTM C94/C94M, using 19 mm maximum size aggregate, and having minimum compressive strength of 21 MPa at 28 days. Grout shall consist of one part portland cement to three parts clean, well-graded sand and the minimum amount of water to produce a workable mix.

Barbed Tape Connection-barbed wire-barbed tape-tie wire

Barbed tape coil tied to middle barb wire at every spiral turn on both sides of outrigger

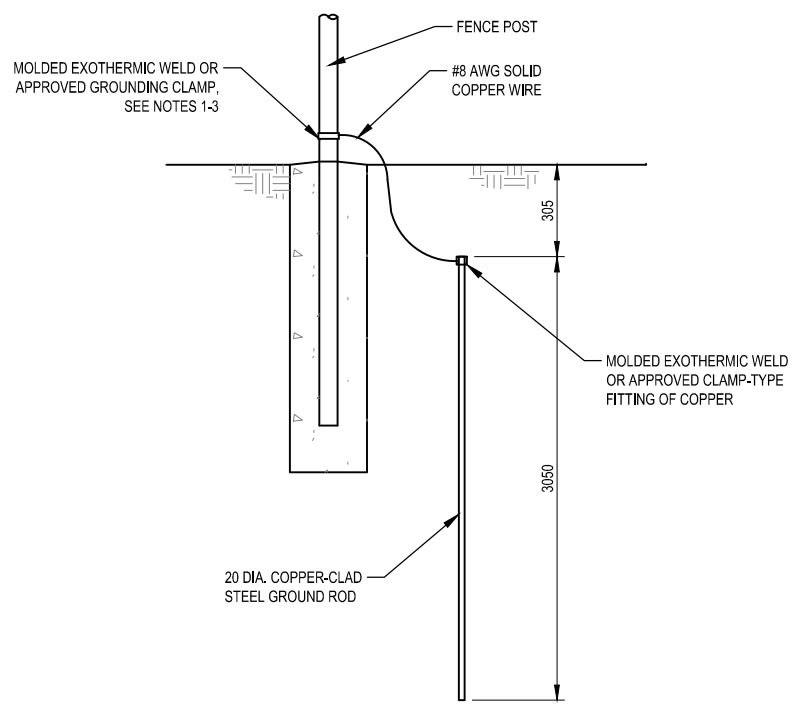

Grounding

Gate Assembly

Provide gate assembly conforming to ASTM F900 and/or ASTM F1184 of the type and swing shown. Provide gate frames conforming to strength and coating requirements of ASTM F1083 , steel pipe, with external coating Type A, nominal pipe size (NPS) 1-1/2. Provide gate frames conforming to strength and coating requirements of ASTM F1043.

Gate Leaves

For gate leaves, more than 2.44 m wide, provide either intermediate members and diagonal truss rods or tubular members as necessary to provide rigid construction, free from sag or twist. Gate leaves less than 2.44 m wide shall have truss rods or intermediate braces. Attach fabric to the gate frame by method standard with except that welding will not be permitted.

Gate Hardware and Accessories

Furnish and install latches, hinges, stops, keepers, rollers, and other hardware items as required for the operation of the gate. Arrange latches for padlocking so that the padlock will be accessible from both sides of the gate. Provide stops for holding the gates in the open position. Each end member of gate frames shall be extended sufficiently above the top member to carry three strands of barbed wire in horizontal alignment with barbed wire strands on the fence.

PADLOCKS

Provide padlocks conforming to ASTM F883, Type PO1, Options B, E, and G, Grade 6. Size 44 mm. Key all padlocks alike.

FENCE INSTALLATION

Perform complete installation conforming to ASTM F567.

Clearing and Grubbing

Ensure all obstacles, roots, plants, trees and vegetation are cleared and removed from work location before proceeding with work. The Contractor shall be aware of any existing underground utilities and infrastructure that may interfere with the work required for installing the proposed security fence.

Line and Grade

Install fence to the lines and grades indicated. Clear the area on either side of the fence line to a distance of 3 m. Space line posts equidistant at intervals not exceeding 3050 mm. Terminal (corner, gate, and pull) posts shall be set at abrupt changes in vertical and horizontal alignment. Provide fabric continuous between terminal posts; however, runs between terminal posts shall not exceed 150 m. Repair any damage to galvanized surfaces, including welding, with paint containing zinc dust in accordance with ASTM A780/A780M.

Excavation and Grading

Clear all post holes of loose material. Spread waste material from excavations within 3 m on either side of fence alignment. In areas of the fence alignment where berms have been removed by others, fine grade the new fence alignment to a total width of 6 m, 3 m on each side of the fence alignment, prior to fence construction. The shall approve the finish grading prior to fence construction. Eliminate ground surface irregularities along the fence line to the extent necessary to maintain a 50 mm clearance between the bottom of the fabric and finish grade.

Chain link fabric installation

a.Install chain link fabric on the side of the post indicated. Attach fabric to terminal posts with stretcher bars and tension bands. Space bands at approximately 381 mm intervals. Install fabric and pull taut to provide a smooth and uniform appearance free from sag, without permanently distorting the fabric diamond or reducing the fabric height. Fasten fabric to line posts at approximately 381 mm intervals and fastened to all rails and tension wires at approximately 610 mm intervals.

b.Cut fabric by untwisting and removing pickets. Accomplish splicing by weaving a single picket into the ends of the rolls to be joined. The bottom of the installed fabric shall be 50 mm plus or minus 13 mm above the ground.

c.After the fabric installation is complete, exercise the fabric by applying a 222 newtons push-pull force at the center of the fabric between posts; the use of a 133 newtons pull at the center of the panel shall cause fabric deflection of not more than 63.5 mm when pulling fabric from the post side of the fence; every second fence panel shall meet this requirement.

SUPPORTING

Install barbed wire supporting arms and barbed wire as indicated on the drawings. Anchor supporting arms with 9.5 mm diameter plain pin rivets, with studs driven by low-velocity explosive-actuated tools for steel, wrought iron, ductile iron, or malleable iron. Studs driven by an explosive-actuated tool shall not be used with gray iron or other material that can be fractured. Use a minimum of two studs per support arm. Pull barb.

Line Post Extension Arms

More Security Fence Panels:

Security fencing system: 358 mesh panel, razor barbed tape wire, Y fence post

Security Modular Fence, Anti Climb Protective Low Carbon Welded Metal Wire Mesh Fence for Airport/Prison/Farm/Ranch

Barbed Tape Alignment - include barb tape coil.